Kim Esbensen challenges commercial laboratories to add primary sampling to their range of responsibilities. Kim’s “tale” of two fictional laboratories should certainly provoke some comment, and concludes in the next issue.

Sampling Columns

10th World Conference on Sampling and Blending

Correct sampling and analysis of raw materials are essential to ensure well-documented product quality and to contribute to a reduced environmental footprint. To this end, the WCSB10 conference covers the latest research and application experience of the Theory of Sampling and Blending.

31 May–2 June 2022, Kristiansand, Norway

Pages

The story of Pierre Gy, who founded the Theory of Sampling (TOS), is a remarkable one, and his work is still the basis of representative sampling today.

The last sampling columns have focused on the advantages the Theory of Sampling (TOS) can bring to companies, producers and manufacturers significantly reducing costs due to inferior sampling, and maximising efficiency and logistics. Here instead we take a look at sampling from the point of view of buyers, consumers and from a broader societal perspective, exploring the economic benefits and other advantages (e.g. transparency) that can be obtained through proper sampling. We address the point of view of the ultimate users and beneficiaries of TOS, on the market place or elsewhere. We are going to explore the other side of the coin, the one linked to the ethical and moral obligations that pertain to decision-makers of responsible public and governmental bodies, which indeed should apply equally also to producers and manufacturing companies.

Pentti Minkkinen and Kim Esbensen present case histories and examples all focusing on the potential for economic loss or gain—by following, or more importantly, by not following TOS.

Sampling takes place every day in everybody’s daily life. Consciously or unconsciously, we all take decisions regarding how to select and collect the things we need, be those vegetables or coffee in the supermarket, or material for academic research projects—with everything in between. Those who have been curious enough to reflect on everyday decision-making processes, discovered immediately that sampling decisions often make all the difference. This is why an incipient theory started to be elaborated. One individual, more brilliant than others, made a giant step forward in the evolutionary thinking on sampling and developed what became the Theory of Sampling (TOS); his name was Pierre Gy. Here, we discuss cases both pro et contra TOS.

Karin Engström, LKAB mining, Kiruna, Sweden, continues to present illuminative cases from process industry. Here she reveals more from her ongoing PhD project showing application of variographic characterisation for on-line continuous control of process sampling systems, including the one that was validated according to current ISO standards guidelines in the previous column (monitoring a particular iron ore pellet stream). Together, the cases presented constitute a broad didactic showcase of the power of variographic analysis and problem-specific interpretations.

This feature forms an intermezzo in the current segment of process sampling columns. We have asked Karin Engström, Luossavaara Kiirunavaara AB (LKAB), Kiruna, Sweden to outline how industrial validation of a process sampling system takes place following ISO standards guidelines.

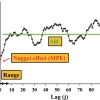

Pierre Gy, the inventor of the Theory of Sampling (TOS), pioneered applications of variography to understanding large-scale variability in process plants and process control from as early as the 1950s and devoted a major part of his TOS development period to this subject. The variogram allows one to identify sources of variability and provides valuable insight into correlations between successive samples. Neglect or poor understanding of the data analytical capabilities of the variogram means that it has not been widely applied in process control until now, except in industry sectors which have embraced TOS (mining, cement and certain parts of the process industries) because of the overwhelming consequences of making wrong decisions when treating vast tonnages—the consequences of wrong decisions are simply too great. Failure to address stream heterogeneity means that conventional statistics and Statistical Process Control (SPC) too often fail to identify and distinguish the true sources of variability in a process stream. For each type of heterogeneity, there is a matching variety of process variability. Although the method is powerful in terms of the insights one is able to gain in regard to plant performance and management, examples of the application of this particular method have been suspiciously little notable in the literature.

After the previous column’s introduction to the why, the how and the technicalities involved in process sampling and variographic analysis, it is time for a bonanza of applications and case histories covering as broad a practical scope as possible. In this column, we introduce the critical prerequisites for the variographic experiment, by focusing on the importance of TOS-correct increment extraction for proper variographics. This issue cannot be overemphasised.

This is the first of a number of columns dealing with process sampling, i.e. sampling from moving streams of matter. As will become clear there is a great deal of redundancy regarding how to sample both stationary and moving lots, but it is the specific issues pertaining to dynamic lots that will be highlighted.